From contactless payments to store security, including our passports, RFID (Radio-Frequency Identification) technology is everywhere. It is so integrated into our daily lives that we almost forget to wonder how it works. Yet, behind these small labels lies surprisingly intelligent engineering.

This article relies on the explanations of expert Dr. Hadi CHEHADE, a doctor of engineering in telecommunications and computer science specializing in RFID, to learn more about how the RFID tag works. This guide dives into the heart of the RFID tag to decipher its secrets: its anatomy, the invisible dialogue it establishes with readers via radio waves, and its concrete applications that are transforming both industry and our daily lives.

What is an RFID tag?

An RFID tag (or RFID label, transponder) is an electronic device that contains a chip and an antenna, usually mounted on a support called a substrate or encapsulation. The chip stores data (unique identifier, product information, various parameters) and manages communication logic, while the antenna captures and reflects radio-electric energy back to the RFID reader.

The RFID tag can be integrated into a paper label, a plastic card, a badge, an industrial casing, or directly into a product, allowing the solution to be adapted to the mechanical, thermal, or chemical constraints of each application.

The main families of RFID tags

There are four main categories of tags, depending on their power supply mode and electronic architecture:

Passive tags

🔷 Battery-free, they recover all their energy from the electromagnetic field emitted by the reader.

🔷 These are the most widely used for logistics, retail, and industrial traceability because they are inexpensive, thin, and easy to integrate into labels or packaging.

Semi-passive tags (or semi-active)

🔷 They include a small battery that powers the chip, but radio communication is done like a passive tag, by backscattering the reader's signal.

🔷 This allows for better sensitivity, increased range, and the potential powering of sensors (temperature, shock, humidity) without having to transmit continuously.

Active tags

🔷 Equipped with a battery that powers both the electronics and radio transmission, they can spontaneously send signals over tens or hundreds of meters.

🔷 They are suitable for Real-Time Location Systems (RTLS) and tracking high-value assets across large areas (hospitals, industrial sites, construction sites, transport).

"Chipless" tags (without a chip)

🔷 A new generation in research and development, they do not integrate an integrated circuit: identification relies on the specific electromagnetic signature of the antenna or printed pattern. 🔷 The goal is to further reduce costs and enable printable labels on a very large scale, at the price of higher complexity on the reader side and more limited memory capacity.

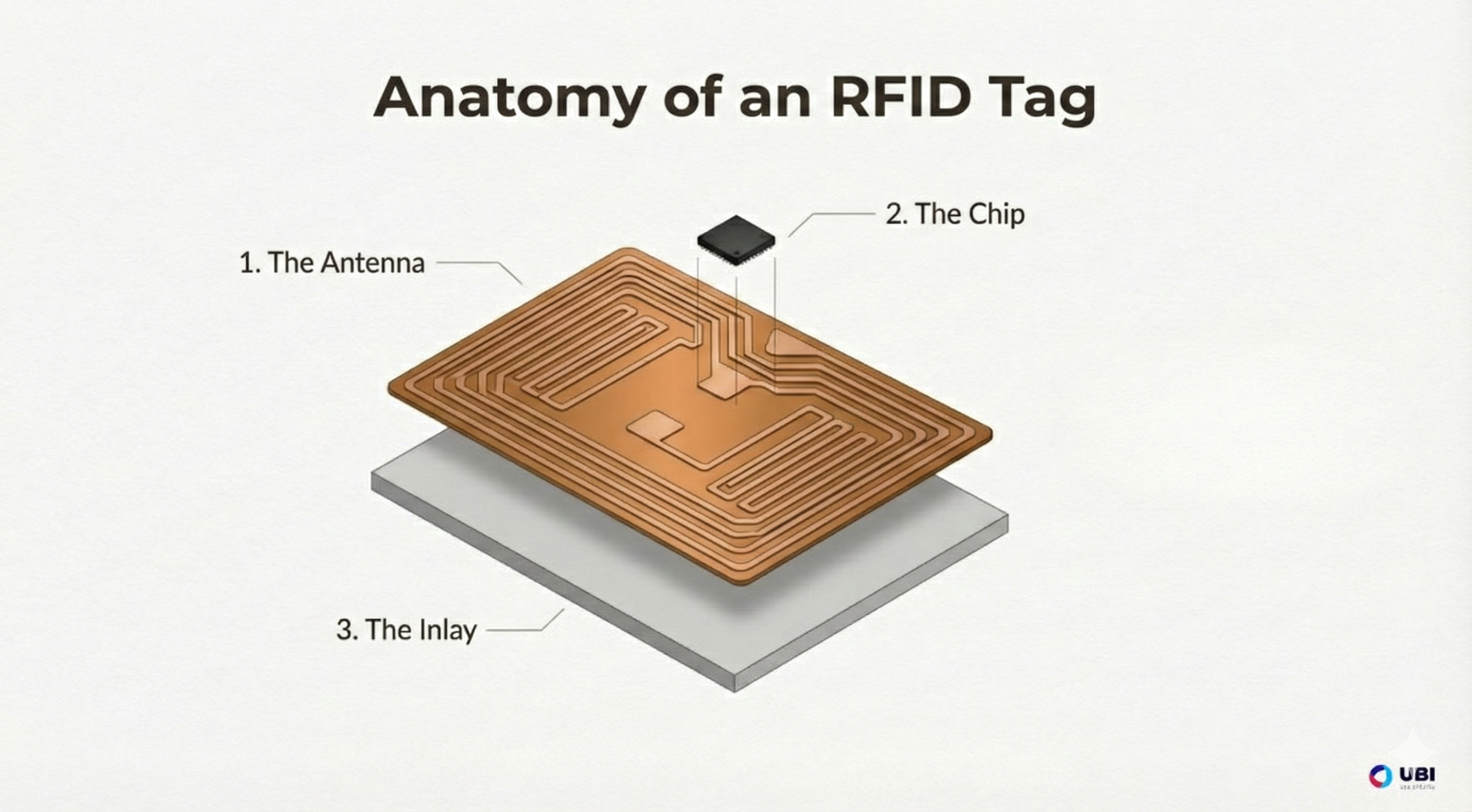

What is a passive tag made of?

The passive tag, the most common format, relies on a minimalist but formidably effective architecture. It is built around three inseparable components:

1. The antenna: the energy sensor

Generally made of aluminum, copper, or conductive ink, the antenna is the point of contact between the tag and the outside world.

Dual function: It acts as a "solar panel" for radio waves (capturing energy to power the chip) and as a transmitter to send data back.

Geometry: Its shape (loops, dipole) and size are calculated specifically for a frequency (LF, HF, UHF) and a given environment. A poorly adapted antenna (wrong orientation, presence of metal) will lead to a drastic loss of range.

2. The electronic chip (Microcircuit): the brain

This is the intelligent heart of the device. Despite its tiny size, it ensures three critical functions with minimal energy consumption:

Identification: It stores the unique identifier (EPC - Electronic Product Code) which allows distinguishing one object among thousands.

Memory: Besides the EPC, it can contain user data (batch number, expiration date) and password-protected secure areas.

Protocol: It manages the communication standard (e.g., EPC Gen2 / ISO 18000-63) to ensure interoperability with any reader on the market.

3. The support and encapsulation: the armor

The chip-antenna assembly is mounted on a substrate (paper, PET plastic). Depending on usage, this "inlay" can be encapsulated in a robust housing. This casing determines the tag's resistance to shock, humidity, extreme temperatures, or industrial washing.

How does the tag activate and communicate?

The "miracle" of the passive tag lies in its lack of a battery. Everything happens in a fraction of a second according to a precise cycle:

1 - The reader emits a radio wave.

2 - The tag's antenna captures this wave and converts it into electrical energy.

3 - This energy activates the chip, which can then respond to the reader.

Communication between an RFID reader and a passive tag takes place in two phases:

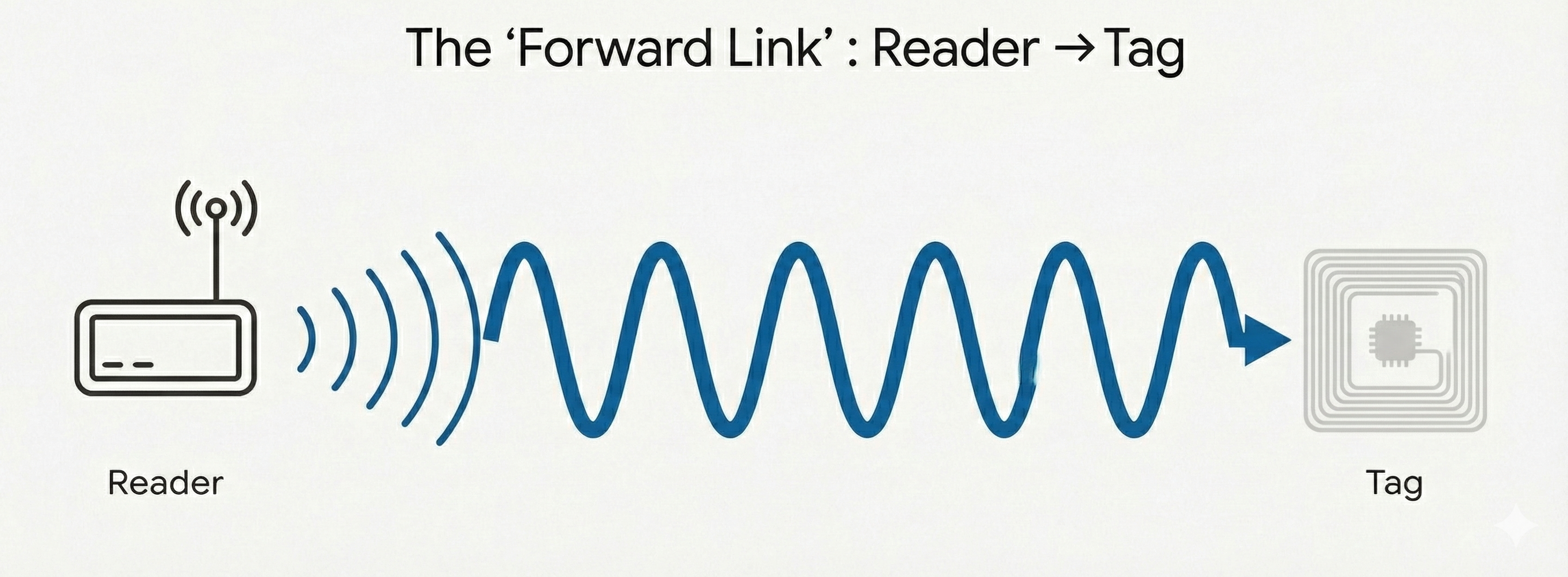

Reader → tag (Forward link)

The principle is electromagnetic induction. The reader sends a radio signal that has a dual role: providing energy to the tag and transporting commands (interrogation, read request, write, lock, etc.).

Once the sensitivity threshold is reached, the chip powers up, synchronizes its logic to the received signal, and begins to interpret commands according to the defined protocol.

The analogy: This is exactly the principle of wireless charging for your smartphone, but at infinitely lower power. As soon as the received energy exceeds the chip's "sensitivity threshold", it wakes up.

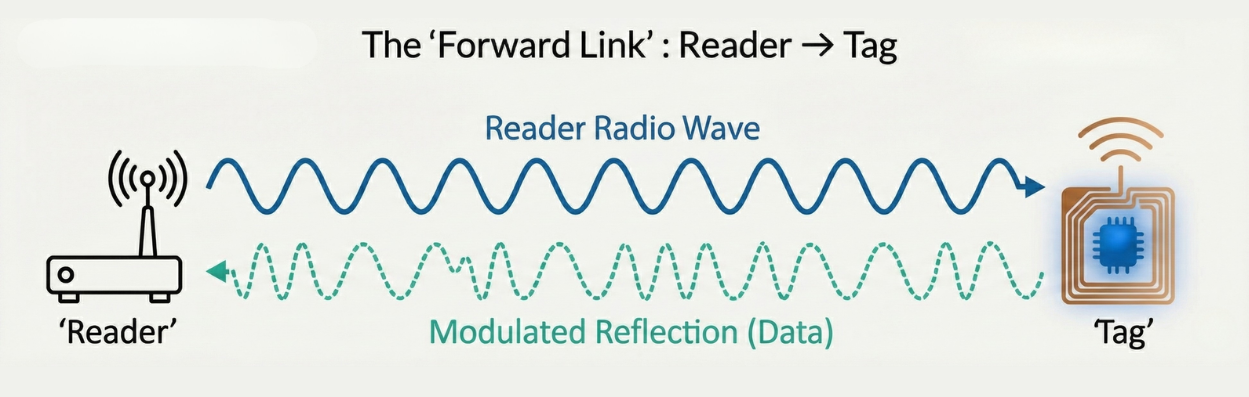

Tag → reader (Backward link)

The tag does not generate its own wave: it sends information back by modulating the received signal via a mechanism called backscatter.

By rapidly changing the state of its antenna (for example, between two impedance levels), it very slightly modifies the reflected power; the reader decodes these variations to reconstruct the data bits.

The mechanism: The tag returns information (its EPC) by modulating the echo of the incident signal. The reader detects these tiny variations in the wave it sent itself and decodes them as 0s and 1s.

This mechanism is fast enough to converse with many tags in parallel, thanks to anti-collision algorithms that organize responses to avoid them "stepping on each other".

RFID Frequencies and their applications

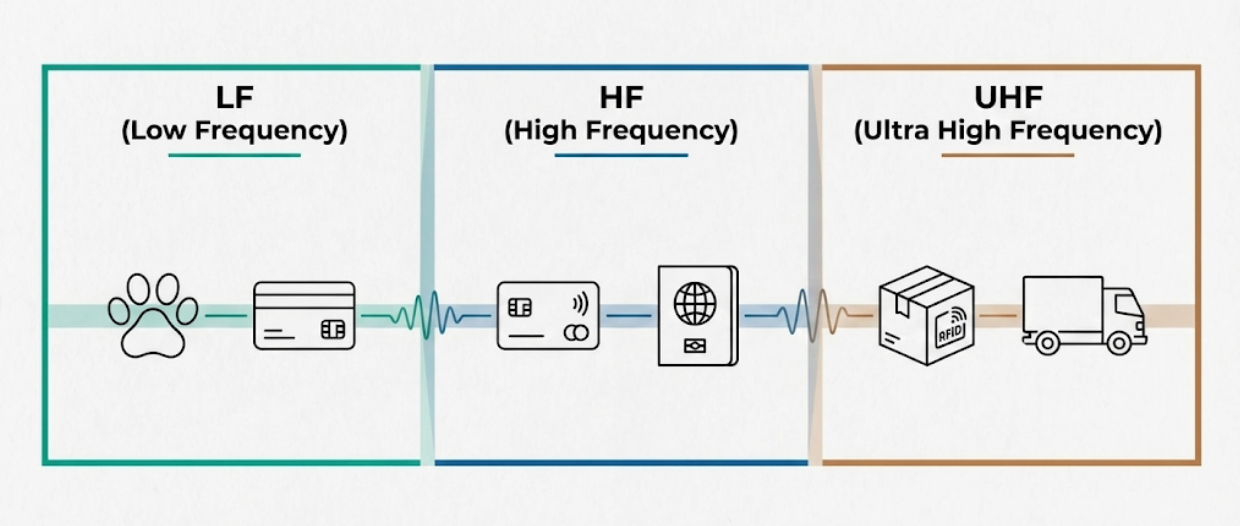

RFID tag behavior depends heavily on the frequency used.

|

Frequency |

Typical usage |

Approximate range |

|

LF (125 kHz) |

Access, animal ID |

A few cm to ~50 cm |

|

HF (13.56 MHz) |

Contactless cards, passports, NFC |

Up to 1 m (often < 10 cm) |

|

UHF (860–960 MHz) |

Logistics, supply chain, tolls |

Up to 12 meters |

Tag performance also depends on its operating frequency: Each frequency is adapted to specific uses based on range, object type, and environment.

Factors influencing RFID reading

Several elements can affect reliability and range:

🔷 Materials: metal and liquids disrupt reading.

🔷 Orientation: poor alignment of the tag relative to the reader decreases reception.

🔷 Distance: the signal weakens with distance.

🔷 Radio interference: WiFi, Bluetooth, and industrial machines can disrupt communication.

🔷 Tag density: multiple tags in the same zone can create collisions.

Optimizing installation and adapting parameters to environmental constraints is crucial for reliable performance.

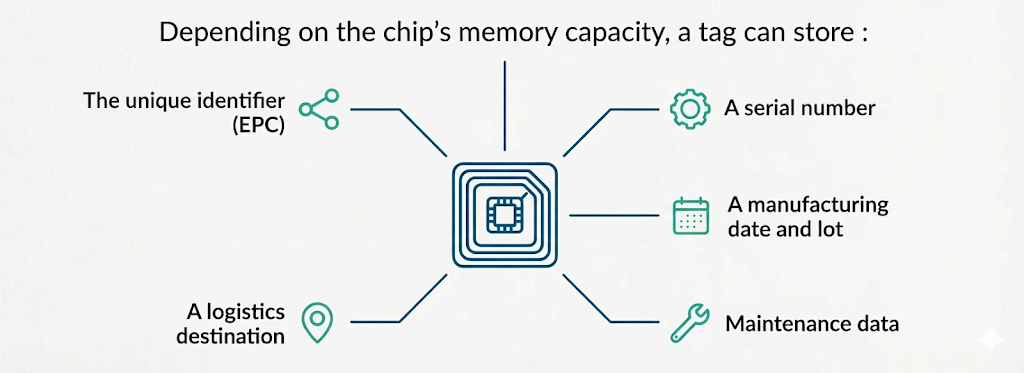

What can be stored in an RFID tag?

An RFID tag can contain:

A unique identifier, often read-only, which serves as a key in information systems (linking to a database).

Additional data in user memory: serial number, manufacturing batch, date, status, logical location, configuration, maintenance parameters, etc.

Potentially secure information, password-protected or irreversibly lockable, to prevent unauthorized modification or cloning.

One of the great strengths of RFID, compared to barcodes, is the combination of three elements: no line of sight required, simultaneous reading of many objects, and the ability to write or update certain information directly on the tag.

RFID vs Barcode: the traceability duel

Now that the technology seems clearer to you, a pragmatic question naturally arises: why switch to RFID when the "good old" barcode seems to do the job? While the barcode remains the king of checkout counters, RFID has nevertheless changed the rules of the game behind the scenes. Let's compare these two technologies to understand why one doesn't necessarily replace the other, but surpasses it in many areas.

These two methods are often opposed, but they meet different needs (and budgets). Here are the 4 fundamental differences that separate these two worlds.

1. The end of "Line of Sight"

This is the most critical difference.

Barcode: It is optical. The scanner must imperatively "see" the label. If the code is dirty, poorly printed, torn, or simply hidden behind a carton on a pallet, reading is impossible.

RFID: It is radio-frequency. Waves pass through cardboard, wood, plastic, and even some construction materials. You can identify the contents of a closed package without ever opening it.

2. Bulk Reading

Barcode: This is a sequential technology ("one by one"). The operator must aim at each label individually, which takes time and requires labor.

RFID: It allows for simultaneous reading. An RFID portal can read several hundred tags in a few seconds (for example, an entire pallet of clothes or spare parts) as it passes on a conveyor belt, without any human intervention.

3. Dynamic and rewritable memory

Barcode: This is static data. Once printed, the code does not change. It generally only contains a reference (like a license plate) that links to an external database.

RFID: The tag is a living "digital folder". You can not only read data (serial number, manufacturing date), but also write new information to the chip throughout the supply chain (e.g., adding "quality control: validated" or "shipped on 12/05").

4. The cost factor: the barcode's advantage

This is where the barcode retains its throne. Printing a barcode costs a fraction of a cent (just ink and paper). An RFID tag, although its price has dropped considerably, involves a material cost (chip + antenna + assembly) that is still counted in euro cents. For very low-value products (like a pot of yogurt), the barcode remains unthronable for now.

Simple analogy to understand RFID

Imagine a flashlight and a mirror:

🔷 The reader is the flashlight that illuminates.

🔷 The tag is a small mirror that reflects a specific shine.

Each mirror (tag) reflects a unique shine corresponding to its identity, exactly like a passive RFID tag sends back its identifier to the reader.

.png?width=2784&height=1536&name=Gemini_Generated_Image_kccxelkccxelkccx%20(1).png)

Much more than a simple identification method, RFID has become the backbone of an interconnected world. From industrial logistics to contactless payment, its strength lies in its ability to make objects "intelligent" from a distance.

But as we have seen, technology is not everything: understanding the anatomy of a tag and its interactions with the environment is the key to transforming a simple project into an operational success. The story does not end there. With the advent of chipless tags and next-generation protocols, RFID is beginning a new mutation, promising ever more economical solutions and limitless traceability.

.png)